What is inventory management and why is it important

“SOLD OUT”, OUT-OF-STOCK” are the common terms that normally customers come through when they go shopping for their required product online or in-store.

Table of Contents

What Is Inventory?

What is Inventory Management?

Inventory Management is the most simplified term used to cover major aspects of the supply chain under one umbrella. This may include a sales forecast, supply chain management, warehousing, product order management and fulfilment solution. In short, we can say it as roots that make business stand or fall. If managed properly, it can grow the business further, if not then a business owner should get ready for great disasters.

Proper inventory management may bring numerous benefits to the business which will be discussed later in this article. Smart retailers make use of an efficient centralized inventory management system which helps them keep things aligned. Good software can track, plan and keep notified the user regarding all inventory matters.

Inventory Management Process

The inventory management process begins with receiving an order which keeps on updating related systems meanwhile till the order is shipped. Updating at every step is highly necessary for a good system. In the case of specialized inventory software, it updates the user about sales forecast and informs timely about low stock or out of stock products. In this way, the system helps reduce complaints related to out of stock products.

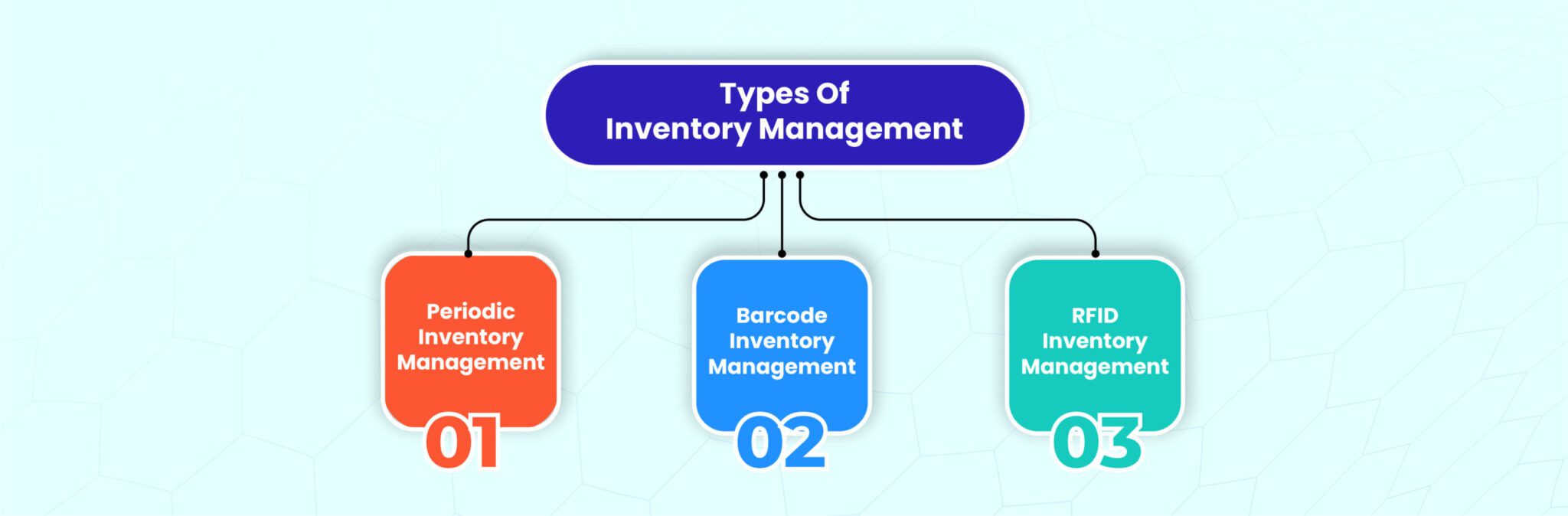

Periodic inventory management

This type of inventory management system plays with starting and ending numbers of products available. It keeps track of the physical count of inventory which keeps on updating at regular intervals. By deducting ending inventory from starting inventory it helps to check the cost of goods sold (COGS).

Barcode inventory management

Most e-commerce businesses tend to use barcode inventory management systems. This is far more reliable than any other because each product and its type has a unique identifier which is known as the barcode of that product. Inventory is managed based on those barcodes. Barcodes can embed information related to the supplier, product dimensions, weight etc. in the form of a specialized code.

RFID inventory management

Radio Frequency Identification (RFID) is another very effective way of inventory management through which the movement of each product with its complete information can be tracked and timely notified. Products in this type of inventory management are given a unique serial number which provides complete product info when tracked down. RFID increases overall visibility with automatic inventory visibility.

The aforementioned are types of inventory management but do you know why it is important to manage inventory?

Importance and Benefits of Inventory Management

Stronger roots grow firm plants. Inventory acts the same. These are the roots. If these are managed with care, the plant will grow more firm. Managing inventory properly is important for the following reasons:

Produce competitive ability by keeping track of inventory flow

The fast-growing e-commerce industry cannot afford to lack within the system. To bring in the competitive ability within a market inventory is needed to be managed properly. Inventory management allows merchants to keep track of their inventory.

Improved services

Managing inventory up to the required level lends merchant time to bring about the most optimized strategies for a better service level. Once improved, it can bring in more business opportunities at home.

Optimized storage

Maintaining an adequate level of inventory optimizes the storage capacity of the warehouses or retail stores. This becomes more efficient when inventory management software is used. Optimized storage leads to storage of more sellable products than overfilled stuff.

Higher revenue generation with no more “Out of stock” situation

Referred to the previously mentioned point, proper inventory management helps businesses keep in more sellable goods which bring in higher profits. Non-sellable products are no more than waste for an overall business. So, filling the right inventory is far better to earn higher revenue than filling shelves with non-sellable items. Keeping products which is more in demand helps fight out-of-stock situation as well.

A step towards go Green policy

Generating the right type of product consumes exactly the right resources. This reduces wastage and hence contributes to cost control as well. For example, if companies produce injectable supplements more than oral supplements. And demand enforces more oral supplements than the utilized resources will get wasted.

Demand and supply balance

Proper inventory management provides clarity on demand and supply chains management as well. Once a business owner is aware of the product flow metrics, they can optimize demand and supply levels as well. This is highly necessary for FMCG companies.

Consistency in product supply

Once the merchant is aware of the demand for the product they can produce the right amount of that product. This brings consistency in product manufacture and supply.

Brands' loyalty with timely delivery

Consistency in the production of the product which is more in demand builds brand loyalty and encourages customer satisfaction, as well as the product, can be delivered timely depending upon its availability. Regular supply brings in customers’ confidence. This level can only be achieved with proper inventory management.

Reduce manpower makes it further cost-effective

Higher productivity of products demands more manpower and resources. However if the brand is aware of the exact product their customers need, production becomes more specific reducing extra manpower hence reduction in overall manufacturing cost.

Enhanced product quality

Inventory management keeps merchants focused on the right product manufacturing. This lends time to enhance the product quality welcoming further brand loyalty.

Techniques of inventory management

Tech has benefited inventory management in different ways. Some of the major techniques of inventory management are mentioned below:

- ABC Analysis – Helps in identifying the product in demand

- Batch Tracking – Tracks product expiry

- Bulk Shipments – This helps in bulk buying, storing and shipping of inventory

- Cross-docking – This technique is used when direct unloading of products is needed between supplier and delivery truck. No warehouse needed

- Demand forecasting – Provides product demand forecast

- Dropshipping – The product is shipped directly from the warehouse to the end customer.

- Economic Order Quantity (EOQ) – This is to check the amount of inventory needed by the company to avoid other related costs of a product.

- FIFO and LIFO – First in First out (FIFO) involves the movement of the oldest stock first. In Last in First out (LIFO) the most recently-purchased inventory is sold first considering is more expensive than the old one.

- Just-In-Time Inventory (JIT) – allows the lowest stock level management to keep things simplified.

- Lean Manufacturing – Removing wasted inventory which does not provide any benefit to the end customer.

- Material Requirements Planning (MRP) – Planning, scheduling and inventory control for manufacturing is involved in this technique.

- Minimum Order Quantity – Minimum order quantity is allowed for maintaining lower stock levels keeping costs low.

- Reorder Point Formula – This technique allows businesses to check the minimum amount of stock needed before reordering and managing it accordingly.

- Perpetual Inventory Management – real-time stock sales.

- Safety Stock – Surplus stock is kept in case the company do not provide it on an immediate basis.

- Six Sigma – A data-based method to remove wasted inventory.

- Lean Six Sigma – Combination of lean management and six sigma to remove wasted inventory.

How Ginkgo helps to manage inventory

Ginkgo Retail provides a centralized inventory management system that connects retail with online. It helps boost productivity and profit. It helps save time wastage on meaningless tasks like inventory updates one by one across all channels. It is a multi-channel inventory manager which works smoothly even if inventory grows. With Ginkgo, you do not have to use a dedicated warehouse. It let every store become a warehouse bringing efficiency and accuracy to inventory management.

Ginkgo can be integrated with other ERPs like Microsoft Dynamics, Retail Pro, Oracle, Candela, POS GTECH and much more. It automates all processes whether it is online or brick and mortar stores reducing the in-store transfer of stock.

Let Gingko take your pain of managing inventory for you.

Written by

Usman Ali

Experienced Digital Marketer with a demonstrated history of working in the eCommerce and digital marketing industry.